Hydraulic Pulverizers

Built to the highest quality standards in the industry, Indeco’s new IFP fixed and IRP rotating pulverizers are ideal for pulverizing reinforced concrete materials and structures, allowing operators to separate the concrete from the rebar.

IFP and IRP Series Concrete Pulverizers

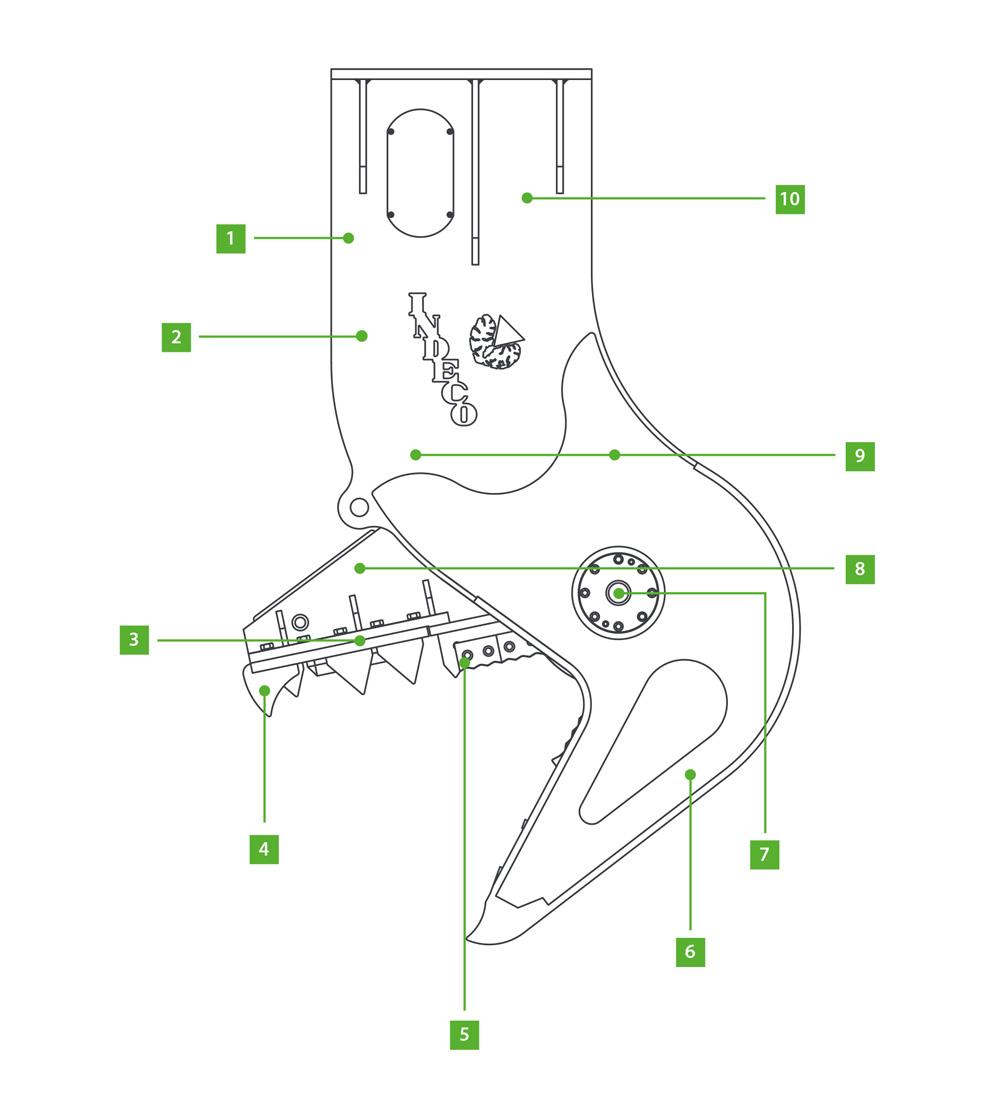

Utilizing the most technologically advanced materials and specifically engineered to withstand high levels of pressure, wear and abrasion, Indeco’s new IFP and IRP Series pulverizers feature an innovative design that provides better grip, makes them easier to handle and enhances the hydraulic energy to most efficiently apply to the demolition. The unique shape of Indeco’s pulverizers helps to reduce the force variation between the start (maximum opening) and end (minimum opening) of the operation. This results in greater demolition efficiency and reduces labor time and stress on the excavator.

1. Position of the hydraulic cylinder protects the rod.

2. Exclusive geometric design ensures that the pulverizing force remains as constant as possible between maximum and minimum opening.

3. Special latches.

4. Interchangeable teeth mounted on a bolt-on plate with tooth sockets.

5. The distance between the cutters located inside the jaws can be adjusted, so that steel rods inside reinforced concrete can be cut more efficiently and both sides of the interchangeable cutters can be used.

6. Innovative design provides better grip and improves maneuverability, extremely rigid structure prevents buckling.

7. Greasing system for better lubrication of moving mechanical parts.

8. Wide opening between the jaws.

9. Frame and jaws made with HARDOX®.

10. “Regeneration valve” which enables the movable jaw to be closed more quickly under no-load conditions.