Hydraulic Hammers HP Series

Innovative thinking, superior performance, the benchmark in technology for Hydraulic Breakers.

Whether you’re demolishing city buildings, excavating road tunnels, removing slag from blast furnaces, or performing highway maintenance, Indeco North America has a hammer to fit your particular carrier, application, and budget!

Featuring fuel-saving technology, the unique Intelligent Hydraulic System, and available in 21 heavy-duty models from 200 to 25,000 ft. lb. – and now including the amazing HP 25000, the world’s largest breaker – Indeco breakers are system-engineered to fit your brand of excavator, loader, backhoe, mini-excavator, skid-steer loader or stationary boom.

Features & Benefits:

- 3-YEAR WARRANTY on HP 200 – HP 1800 models

- ABF TECHNOLOGY

- Automatic Variance on Speed and Power

- Fuel Saving

- Dual Shock Absorber Systems

- Field-Replaceable Lower Insert Bushing

- Low Operating Pressure

- Simple and Efficient Design

- Custom Bracket Caps

- Power Greasing System

- Quiet Operation

- Single In-body Accumulator

- Strongest Warranty Protection in the Business

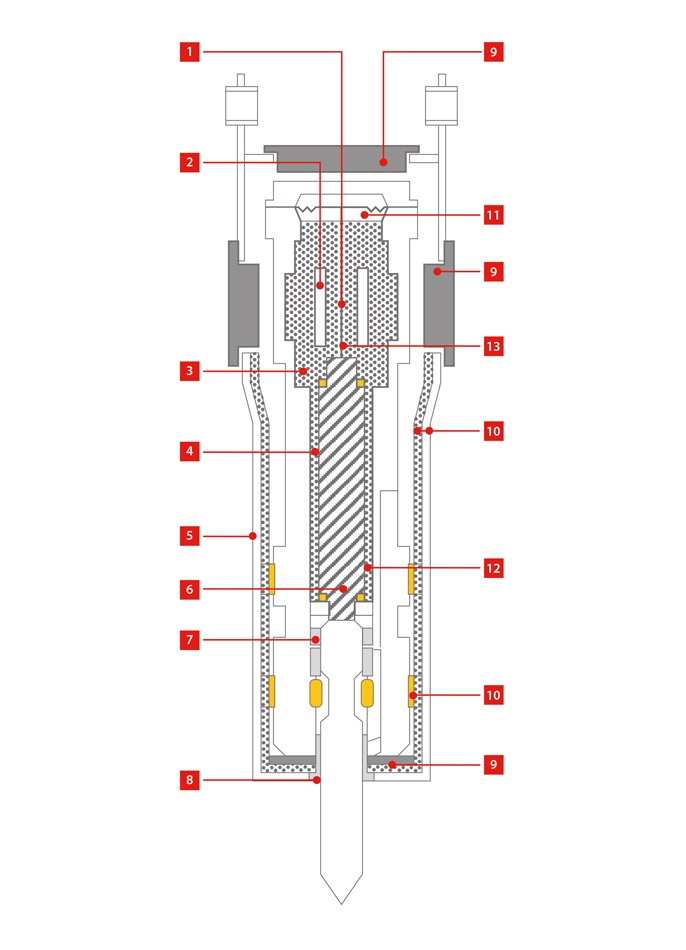

1. Intelligent hydraulic system.

2. The synchronized internal distributor and piston maintain the same axial line.

3. Oil cushion to reduce harmful low-frequency shock waves.

4. Short hydraulic flow pattern with dynamic sealing.

5. Casing in HARDOX© steel.

6. Piston.

7. Centralized greasing point.

8. Quick-change bushing replaceable on site.

9. Lower shock absorber to reduce the axial stress between the hammer.

10. Side shock absorbers to reduce radial vibration and noise level.

11. Upper shock absorber to reduce axial vibration transmitted to the excavator boom.

12. Wear and sound deadening plates.

13. Internal sound-absorbent lining in super-soundproofed Whisper versions and independent housing.

14. Rechargeable nitrogen accumulator.

15. ABF System to eliminate blank firing.

16. FS hydraulic system for lower fuel consumption.